People

In every company, human relationships represent the opportunity to share value. This is why, at Vibram, we carefully cultivate our relationships with employees, communities, and clients.

We are committed to training and raise awareness on issues of sustainability, promotion of diversity and inclusion, support for communities and local regions, and client involvement are the key aspects we see as essential in contributing to the creation of a fair, conscious society.

Customers and local community

We believe cultivating relationships inside and outside our company is fundamental to create and share value. That is why we cooperate with many organisations both to enhance the sustainable development of the shoe sector and to support the well-being of communities.

We want to play our part in the energy transition, choosing renewable energy and reducing our consumption thanks to increasingly efficient processes. We carefully measure the energy consumption required to power our offices and production facilities.

We are operating along two lines: reducing energy consumption through more efficient processes and cutting-edge systems; and using clean energy:

- Focus on the selection of electricity supply sources

- Constant investment in LED technology

- Streamlining production lines by replacing presses, intervening on water pumps, and assessing systems

- Gradual improvement of buildings’ thermal insulation

We have gained an understanding of our direct emissions (Scope 1) and indirect emissions from purchased energy (Scope 2), and we intend to expand on this with a company-wide Carbon Footprint study that also includes indirect emissions along the value chain (Scope 3).

Main outcomes

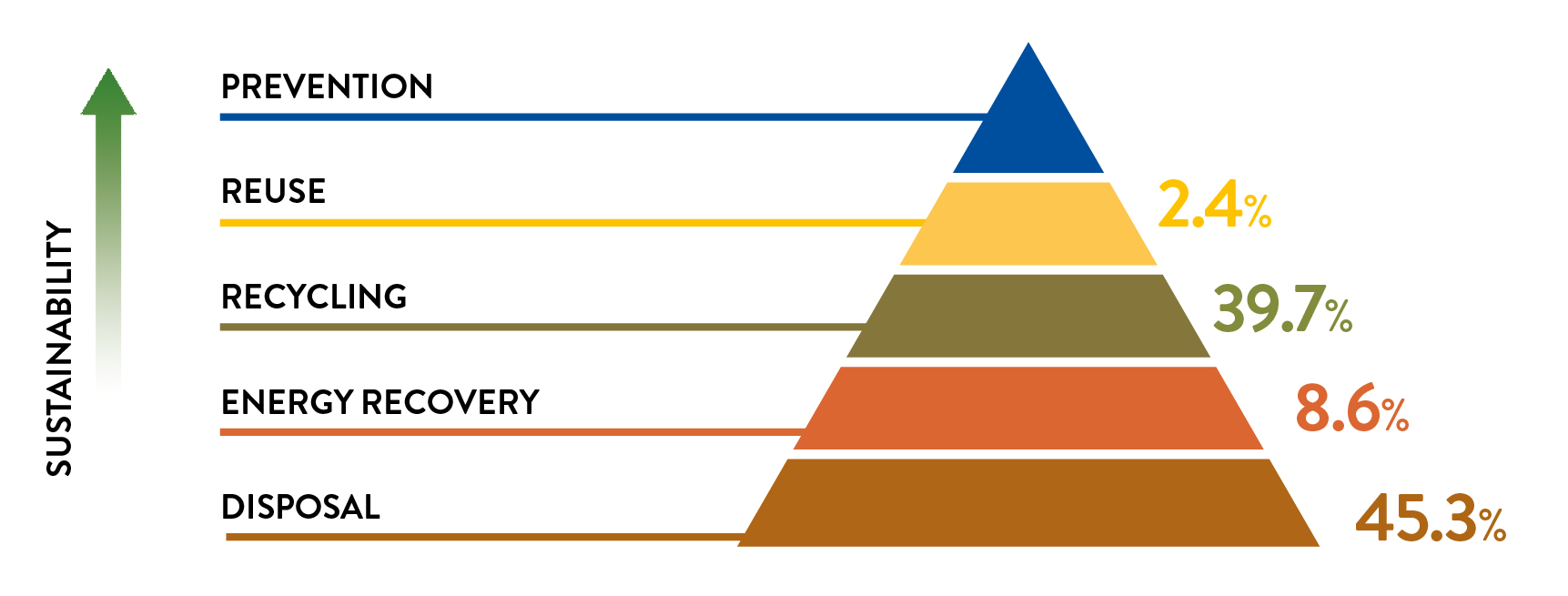

The reduction of waste is one of the key principles of the circular economy. We believe that managing waste virtuously means seizing every opportunity to reuse and recycle, giving new life to waste.

This target can be achieved by working on many fronts: cutting down on production waste; also thanks to more efficient processes; reducing waste from office and consumer materials; and eliminating hazardous waste.

- Continuous monitoring of waste production

- Reuse of waste or distribution to recycling and reuse projects in collaboration with external partners

- Reduction of water use in our production processes

- FSC certification for natural rubber

- Biodegradability level of the ECOSTEP compound certified by Intertek

We carefully examine our products’ production processes and sustainability performance to find new opportunities for the reuse and recycling of manufacturing waste, in line with the principles of the circular economy and ecodesign.

The four areas of action to contribute every day to the zero-waste goal.

- Responsible use of materials and chemicals

- Correct waste management and disposal

- Recovery and reuse of materials within production processes or recycling and reuse for external projects

- Responsible use of water and correct wastewater disposal

- Biodegradability of ECOSTEP Natural rubber components certified by Intertek

To fulfil our sustainability commitments, it is vital to involve all areas of business and foster a responsibility-centered corporate culture. We have defined a clear and efficient organization, with cross-departmental systems and procedures that integrate sustainability into our corporate strategy.

OUR COMMITMENT

We have created a global cross-functional team that sets out the Group’s sustainability strategy and implements it at the local level, supervised by a Strategy Committee.

ACTIONS:

- Circulation of corporate values among stakeholders via the Vibram Ethical Policy

- Updating strategic sustainability objectives

- Data collection and continuous monitoring of sustainability performance indicators

- Allocation of sustainability KPIs to all managers

Our suppliers are more than the name suggests: they are our partners. Each link in the supply chain has to be involved in the pursuit of our sustainability goals. We trust only those suppliers aligned with Vibram’s values and quality standards, which we choose following a preliminary assessment and the successful completion of an audit.

We are also working to integrate the characteristics of the logistical model, commitment to innovation, and the improvement of social and environmental sustainability features into our assessment system. The work to assess and monitor the supply chain that we have undertaken in the past two years aims to foster a shared vision of sustainability and ethical values with our suppliers, involving them in commitments to social and environmental improvement.

Our Actions:

-

Analysis and monitoring of our supply chain

-

Logistical optimization, also with a view to lower environmental impact

-

Audits carried out with the main Chinese subcontractors to ensure compliance with the use of the Higg Index

-

Encouraging the adoption of environmental certifications, such as ISO 14001

-

Assessment and data collection from main subcontractors representing 88% of the total number of pairs soles produced externally

We look into solutions to optimise processes and research new combinations of materials to put on the market, innovative products and services that offer high-level quality and performance for the footwear industry, guaranteeing consistent attention to sustainability and environmental protection. To create products with a lower environmental impact we focus on two areas: selection of materials and durability. On the one hand, we design products with recyclable components and compounds containing natural, bio-based, and biodegradable materials. On the other hand, we develop processing techniques to maximally extend the life of our soles while maintaining optimal performance.

In 2023, we launched two new compounds on the market:

- MORFLEX NATURAL: an expanded EVA-based rubber compound made with up to 50% bio-based contents, circular raw materials coming from agri-food wastes and plastic waste.

-VI-LITE RECYCLE: made with up to 25% recycled Vibram Vi-Lite, in powder or flakes.

Additionally, since 2022, we have developed an LCA software tool capable of measuring the carbon footprint of all our soles and predicting the potential impact of new compounds. This allows our designers to develop new products with improved sustainable performance.